Intelligent lifting device designed for high speed, precision pick & place activities, float mode capable & includes a host of programable selections.

A rigid arm list assist device that can tilt, turn, rotate & upend practically any heavy or difficult to handle load.

Wire rope lift assist device ideally suited for high-speed pick and place handling activities utilizing a variety of gripper tooling options.

An economical short stroke manipulator arm that is extremely capable and suited for machining companies or any handling operations where floor space is at a premium.

A vertical stroke lifting device typically attached to overhead rail systems that can be equipped with a plethora of end of arm tooling.

A hoist based intelligent lifting device that can turn your existing overhead crane into the most advanced ergonomic lifting device.

Vacuum tube ergonomic lifting device deigned to lift porous loads such as bags, boxes, pails, drums & most other loads with speed & precision.

Designed to zero out the weight of heavy tools and can be configure for pick & place handling and be fitted with numerous gripper type tooling.

Designed to work not only as a balancer but also serves as a highly capable “intelligent” lifting device with all the capabilities that one expects in this highest class of lifting devices.

manually powered hoist -based lifter designed for close quarters handing activities, includes and quick attach & release to accept standard tools like scissor grippers, load hook etc.

Lift from over 100-fpm down to unperceptively slow, this proficient tool provides speed, precision & longevity in the most demanding handing activities.

When air power is needed to zero out the weight of your heaviest tools, this tool will allow your team to increase productivity and eliminate repeated lifting ailments.

With capacities up to 400-lbs this versatile tool can be outfitted with an assortment of custom tools such as power grippers, expanding mandrels for roll handling, vacuum cup assembly, roller bed and much more.

Can be customized to grip, tilt and rotate loads up to 2,000-lbs. Battery powered with onboard charger this unit provides unmatched performance, efficiency and safety to any production

lift tables, tilt tables, Available in air powered, hydraulic and spring actuated. Automatically maintains pallets at an ergonomic working height increasing productivity and reducing back strain.

Most of our equipment is available in stainless steel and is ideally suited for food manufacturing operations, pharmaceutical companies or any organization in need of washdown capability.

These Enclosed Track Workstation Bridge Cranes allow for almost effortless movement in the X-Y axis, with capacities up to 4,000-lbs they are the mainstay in modern manufacturing plants everywhere.

Gantry Cranes and Jib Cranes are the most popular ergonomic cranes in the industry, designed for small to medium size operating areas. 1-lb of force exerted by the operator will move 100-lbs of load, this ergonomic ratio will increase productivity and reduce worker injury.

When all you need to do is move in a linear path there is no better solution in the world. Available in free standing and ceiling supported versions, designed so that anyone without experience can easily install these cranes

Jib Cranes available in free standing, wall or column mounted or under hung configurations. These extremely capable cranes are available in capacities up to 1,000-lbs with boom spans up to 16’ long.

The longest lasting cranes in the industry, the running surfaces on the runways and bridge weldments a made of a supper dense hi-strength grade 8 steel that provide years of worry-free use even in the harshest environments.

When you lift and move really heavy loads in severe duty environments, these heavy-metal jib Cranes are the way to go. Standard capacities up to 5-tons, boom spans up to 25’, 360° rotation, powered rotation and can be configured for outdoor use. Custom jibs are available.

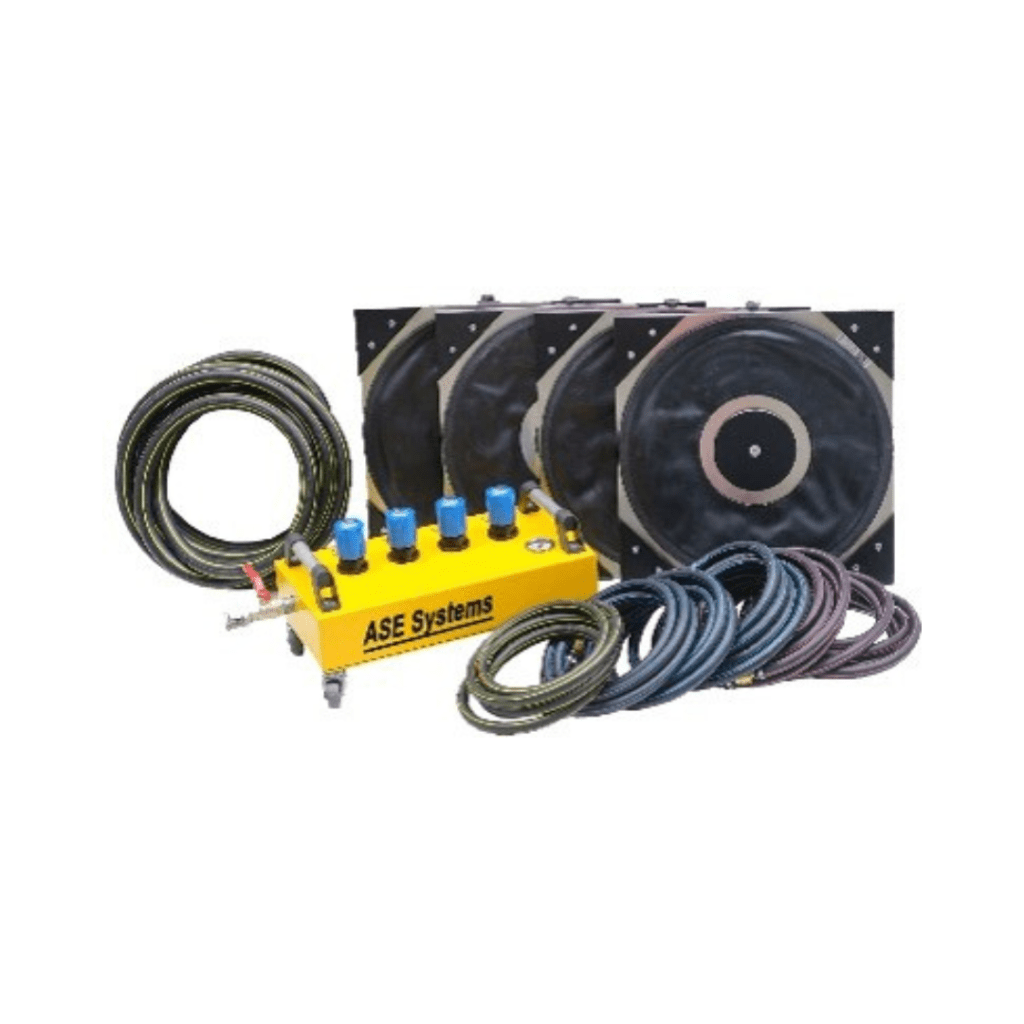

No, this is not a lift assist device but, it can help you move a heavy machine or substantial load with the greatest of ease. Just place the modules under your load, turn on the air and away you go. 1-lb of force will move a 1,000-lb load “wow”! That means you can move a 25-ton load with only 50-lbs of force “yea, read it right”!

Lift Assist Equipment, Lifting Devices & Handling Equipment

ASE Systems brings over 30 years experience specifying and designing ergonomic & productivity enhancing solutions to a broad range of industries that include: Aerospace, Defense Contractors, Manufacturing, Power Generation, Assembly, Marine and more. ASE’s unique ability to provide competitive pricing on a host of lift assist equipment and handling equipment stems from an unmatched combination of integration, customization & strategic partnerships with other world class cutting edge manufactures and systems integrators.

|  |  |

One of the most important factors in any Intelligent lifting device or handling solution is the cycle time which asks the question “how often per minute or hour is the load being moved and or lifted”. The cycle time will determine how much capital needs to be spent for a temporary or lasting solution. Cycle time can be related to the difference between your daily driver and a formula one race car; the daily drive performs many useful tasks but will never be able to match the technology, handling and speed of the formula one racer. The cycle time is one of several analysis questions necessary to determine the size, shape and speed of the individual components that make up your lift handling system. Additional analysis questions include:

1. Length, width & height of the product?

2. Weight of the product?

3. Where and at what height from floor level is the load at time of lift?

4. Distance of movement or area of coverage?

5. Where is the product being placed and at what height from floor level?

6. How high does it need to be lifted in addition to the pick and place points?

7. What is the ceiling height in the handling area?

8. Are there any overhead obstructions such as lights, conduits & pipes in the handling area?

9. Are there any environmental conditions to consider such as outdoor use, wash-down, explosion or corrosion proof?

10. Describe the item to be lifted in detail.

Through analysis of this data will allow ASE to specify a cost effective Material Handling Lift Devices; one that will pay for itself in a reasonable amount of time due impart to savings gained from increased productivity and the reduction of worker injury claims should they exist in your facility.

Overhead Support:

The overhead support is the backbone and one of three necessary components in any integrated handling solution. Commonly referred to as overhead cranes, they come in many styles, configurations, shapes and sizes that include: bridges cranes, workstation cranes, enclosed track cranes, monorails, gantry cranes and jib cranes most of which can be freestanding, ceiling or building column supported. With partners like Gorbel, Demag, Kundel & Cleveland Tram-rail your lifting or handling system can be supported from a variety of ergonomically & technologically advanced overhead crane systems that consist of steel and aluminum enclosed Track Bridge and jib crane systems, I-beam and patented track technology.

Lifting Devices:

Intelligent lifting devices, hoist based manipulators, load balancing, float & programmable lifting systems are features found on the high end of lifting devices and will ensure that your cycle time, positioning and load care requirements are met in accordance with your manufacturing and assembly needs. Basic lifters such as electric, compressed air and manually powered hoist are available in a variety of duty ratings and speed ranges. Lift and control packages are ideally suited for lower cycle of less demanding lifting and handling applications.

End Effectors:

Equally as important to the overhead support and type of lifting device is the product interface, that is to say “what type of device is needed to actually grip the product”. End Effectors can vary from an electric or compressed air powered unit to something as simple as a lifting sling. Vacuum cups, powered grippers, magnetic lifter, expanding mandrel, lifting tongs, parallel grippers are just a few of the standard and custom product interface technology ASE Systems can bring to bare to complete the basis of your handling solution. The final size, shape and mix of components of your end effector will be based upon the answers to your analysis questions.

Auxiliary Equipment:

Once ASE Systems has identified and specified the overhead support system, lifting device, lift tables, tilt tables, and end effector for your application there is a host of support equipment that will increase the ergonomic value as well as decrease the cycle time that can be achieved by the integrated lifting system alone. Mobile and stationary units that can also move, lift & position your load through the work cell area can be powered or manually configured to meet your individual requirements.

Have Question/Query? Fill this Form to send us a message, we will get back to you shortly!