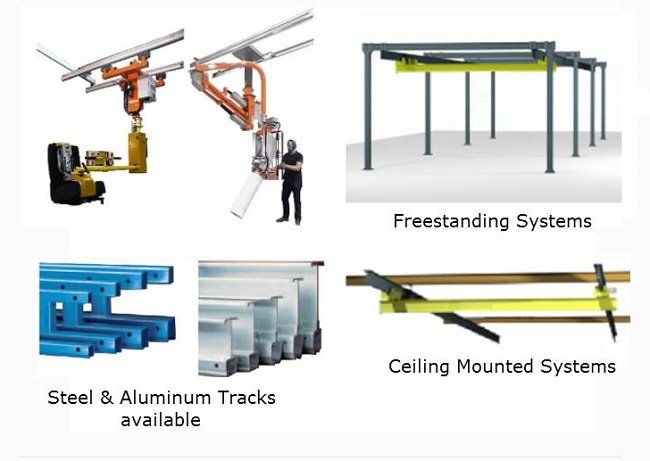

Freestanding & Ceiling Suspended Rail Systems

Both the Mirus and Acer Industrial Manipulators can be inverted and attached to overhead rails which allow the manipulator to traverse a much larger area or service multiple machines in your production environment. In addition to the freestanding or ceiling support structures, the manipulator arm will require an offset load platform which provides a stable structure that the manipulator flange connection plate can be affixed to. The offset load platform is then fastened to a dual rail assembly which in turn is attached to the runway weldments providing multi-directional movement. Support centers can be as little as 2’ or as much as 25’ depending on the length and capacity of the manipulator arm assembly. The offset load platform and the dual rail assemblies can be either manually pushed or configured with power drive options.

Overhead rails are available in both steel and aluminum enclosed track designed to provide years of productive use.

|

Have Question/Query? Fill this Form to send us a message, we will get back to you shortly!