Floor Based Manual Roll Handling

Manipulate Practically Any Roll, Reel Or Coil.

Floor-Based Manual Roll Handling solutions from ASE are engineered to accommodate a range of lifting applications using diverse technologies and attachments. Our products include universal roll handling mandrels, spreader bars, lifting eyes, cradle platforms, and custom-designed end effectors tailored to meet specific needs.

We offer standard capacities of 300, 500, 700, and 1,000 pounds, with roll-handling mandrels available for common core sizes of 3 inches (76.2 mm) and 6 inches (152.4 mm). Custom mandrels can be manufactured for sizes starting at 2.5 inches (63.5 mm) and larger upon request, ensuring flexibility for various roll handling requirements.

Click Below To

Learn More About Our

Floor Based Manual Roll Handling

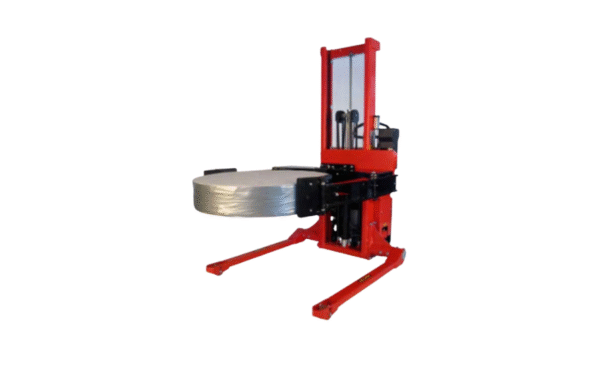

Manual Hydraulic Roll Handlers

Manually powered portable roll handling machine designed as an uncomplicated device for lifting and turning applications

Designed For Lighter Duty Roll Handling Requirements

Manual push, powered lift and easy to maneuver roll handling machines. Intended for light rolls, low cycles and small budgets.

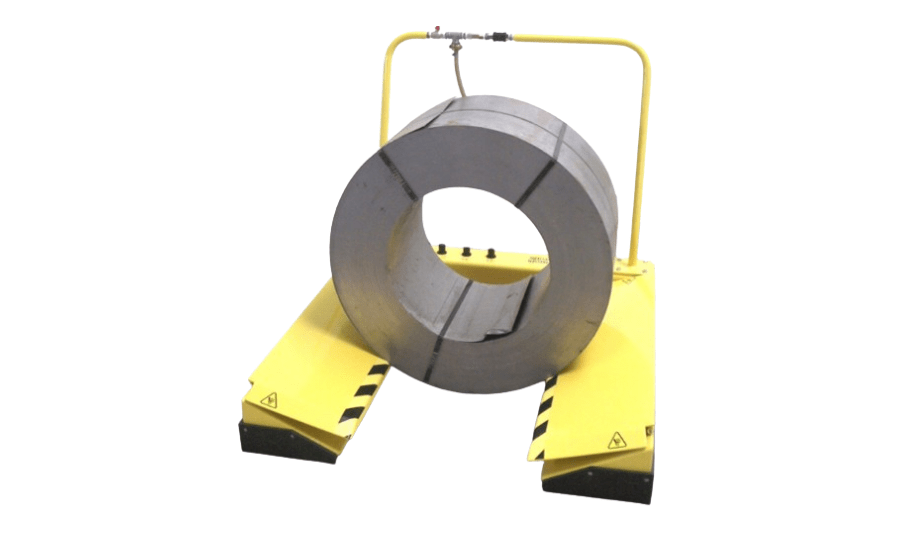

Air Caster Roll Coil and Reel Movers

For Heavy Roll, Coil & Reel Moving Applications & Precise Positioning Capability.

"OD" Roll Lifting & Rotating Machine

Gripping rolls from the outside diameter. 1,100-lb capacity.

Roll Up-Ender

Automate your roll stacking & palletizing operations and reduce manhandling injuries and product damage.

Light To Medium Duty

ERH 200 and ERH 400

The ERH Floor Based Manual Roll Handling machines are specifically engineered to significantly enhance both the efficiency and safety of lifting, turning, and loading rolls within your production process. By eliminating wasted time from repeat adjustments, reducing damage to valuable rolls or shafts, and mitigating ergonomic strain from repetitive push/pull actions, they effectively minimize the inherent risk of injury associated with manual material handling. Moreover, the ERH machines can streamline what was once a cumbersome two-person load handling process into a safe, effortless, and automated one-person operation.

Powered

Lifting

Multipurpose Tooling Designs

Multiple Base/Lift Height Options

Lightweight and User Friendly

ERH 200

200 LBS Capacity

ERH 400

400 LBS Capacity

Click Below To Learn More About

ERH Floor Based Manual Roll Handling Machines

ERH 200

Lifting Capacity Up To 200-LBS

The ERH-200 roll handling machine will effectively increase the efficiency and the safety of lifting, turning & loading rolls weighing up to 200-lbs in your production process. Eliminate wasted time from repeat adjustments, damage to valuable rolls or shafts, ergonomic strain from repetitive push/pull and the inherent risk of injury from manual materials handling. The ERH-200 can also turn a cumbersome, two-man load handling process into a safe, easy and automated one-man operation.

Standard Features

- Quiet 2-Speed Drive

- Lightweight Construction

- Push Button Pendant Control

- Rechargeable Battery Powered System

- Quick Change Battery Box

- Quick Change Tooling Mount

- Standard & Custom End Tools Available

- Battery Charge Meter

- Easy Rolling Wheels & Casters

- 56” Lift Height & Custom Lifts Available

- Straddle & Euro Base legs available

- 3” & 6” Expanding Mandrels

- 1 year warranty.

Manual Roll Tooling

Frontal V-Cradle Tooling

Lateral V-Cradle Tooling

Swivel V-Cradle Tooling

Horizontal Probe Tooling

Dual Probe Tooling

Flat Platform Tooling

Key Features

- 200lbs (91kg) Handling Capacity

- Powered lifting

- Versatile Multipurpose Tooling Designs

- Multiple Base and Lift Height Options

- Lightweight And User Friendly

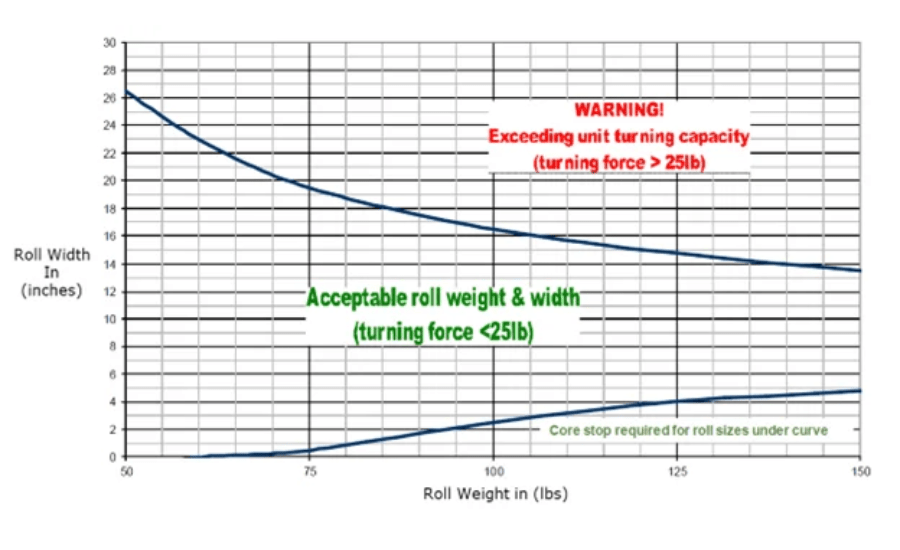

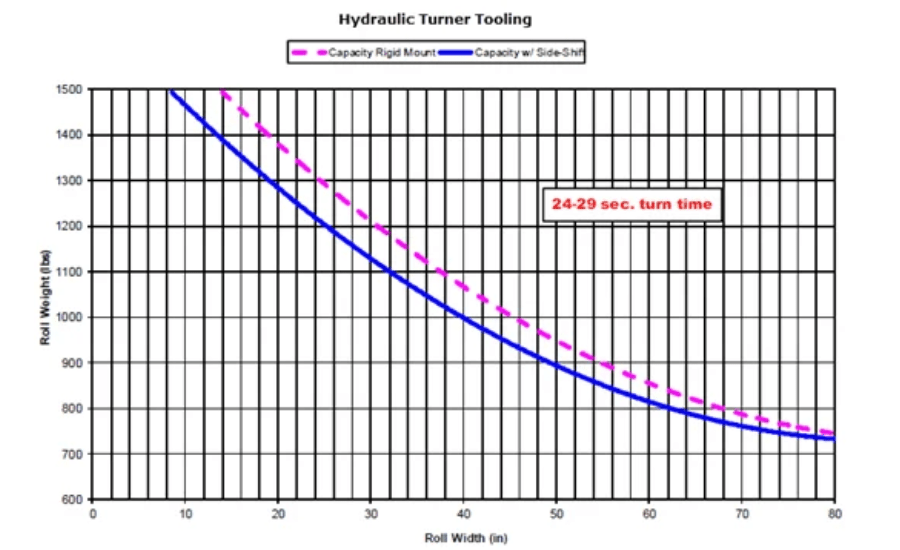

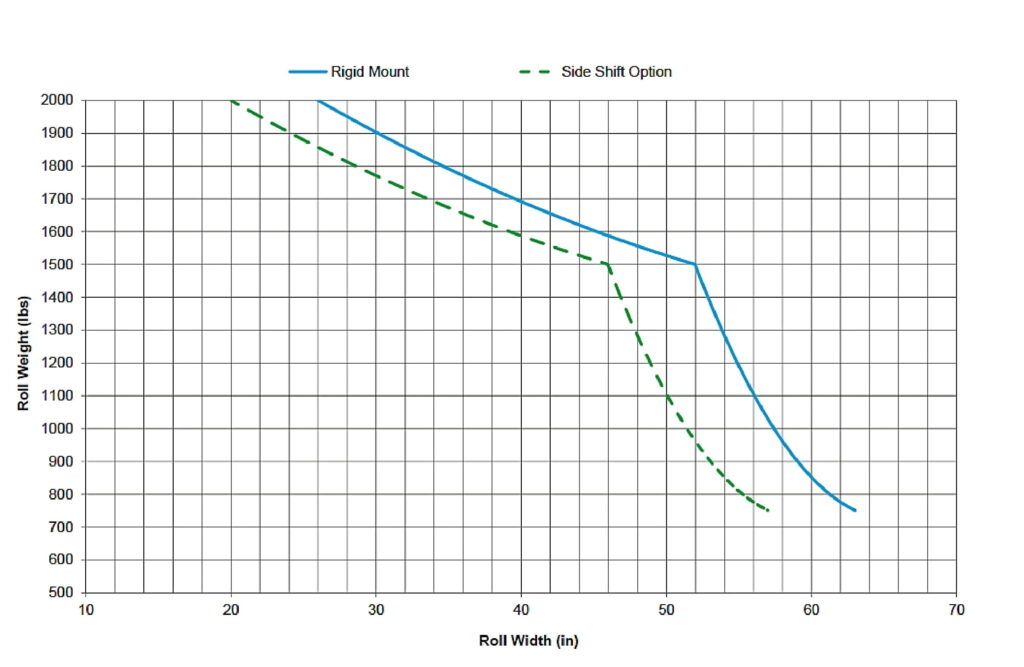

Capacity Chart to determine if your roll can be handled with the ERH-200

ERH 400

Lifting Capacity Up To 400-LBS

The ERH-400 roll handling machine is designed to increase the efficiency and the safety of lifting, turning & loading rolls weighing up to 400-lbs throughout your production process. Eliminate wasted time from repeat adjustments, damage to valuable rolls or shafts can be greatly reduced, eliminate ergonomic strain & injury associated with repetitive push/pull and the inherent risk of injury from manual materials handling. The ERH-400 can also turn a cumbersome, two-man load handling process into a safe, easy and automated one-man operation.

Standard Features

- Quiet 2-Speed Drive

- Lightweight Construction

- Push Button Pendant Control

- Rechargeable Battery Powered System

- Quick Change Battery Box

- Quick Change Tooling Mount

- Standard & Custom End Tools Available

- Battery Charge Meter

- Easy Rolling Wheels & Casters

- 79” Lift Height & Custom Lifts Available

- Straddle & Euro Base legs available

- 3” & 6” Expanding Mandrels

- Powered remote retract available

- Up to 4 powered functions

- 1 year warranty.

Powered & Manual Roll Turner Tooling

Powered OD Gripper Tooling

Base Styles

Specifications

- Max Lifting Weight: 400 lbs (181 kg)

- Pallet Width Max: 48″

- Vertical Travel: 79″ (2000 mm)

- Machine Weight: 250 lbs (114 kg)

- Aluminum & powder coated steel construction

- 24-volt DC operation

- 400lbs (182kg) Handling Capacity

- Powered Lifting

- Powered Rotating

- Powered Grip & Release

- Versatile Multipurpose Tooling Designs

- Multiple Base and Lift Height Options

- Lightweight And User Friendly

Optional Accessories

- Spare battery packs for continuous operation

- Spare mandrel holder

- Anti-telescoping attachment with manually applied, padded O.D. clamp

- Expanding mandrels from 3″ (76.2 MM) to 12″ (204.8,,)

- Automatic mandrel retractor for loading/unloading cantilevered mandrels

- Electric remote mandrel gripper retract

- Manual remote mandrel gripper retract

Capacity Chart to determine if your roll can be handled with the ERH-200

Heavy Duty

HD 1500

The HD roll handling machines are the most precise and powerful battery powered walk behind Floor Based Manual Roll Handling machines on the market today. Used to lift and turn rolls by the core for palletizing, transporting and loading. Holding the rolls inside the core without contacting the valuable material reduces the risk of both material damage and operator injury, saving your company money and valuable resources. With its powerful battery powered electric hydraulic lift & drive unit, driving and maneuvering even in crowded work areas is safe and easy. Both the lifting and turning functions are powered by the truck’s hydraulics. Lever control valves allow lifting and turning in minute increments allowing the operator to make precision alignments fast and easy.

Built-In Battery Charger

Variable Speed Control

Safety Reverseing Switch

Fast and Easy Troubleshooting

HD 1500

1,500 LBS Capacity

Click Below To Learn More About

The HD Floor Based Manual Roll Handling

HD 1500

Lifting Capacity Up To 1,500-LBS

The HD-1500 roll handling machine with 1500 lbs (680 kg) capacity is the most precise and powerful battery powered walk behind roll handling machine on the market today. The HD-1500 is used to lift and turn rolls by the core for palletizing, transporting and loading. Holding the rolls inside the core without contacting the valuable material reduces the risk of both material damage and operator injury, saving your company money and valuable resources. With it’s powerful batter powered electric hydraulic lift & drive unit, driving and maneuver even in crowded work areas is safe and easy. Both the lifting and turning functions are powered by the truck’s hydraulics. Lever control valves allow lifting and turning in minute increments allowing the operator to make precision alignments fast and easy.

Standard Features

- Two speed drive with Turtle / Rabbit switch

- Precision oleodynamic control valves

- Powerful industrial batteries

- Ergonomic drive tiller

- Belly bump reversing switch

- Keyed lock switch and Emergency Stop

- Non-marking wheels

- Reliable electronic controls

- Rugged heavy-duty construction

- All cables and hoses housed within mast assembly.

Specifications

- Max Lifting Weight: 2200 lbs (1000 kg)*

- Pallet Width Max: 48″

- Vertical Travel: Up to 63″ (1600 mm)

- Travel Speed: Variable

- Machine Weight: 895 lbs (406 kg)

- Painted steel construction

- 24-volt DC operation with two 110 Ah batteries

- *Actual capacity depends on roll width and roll weight combined.

Optional Accessories

- Fixed straddle, adjustable or Euro pallet legs

- 63” (1600 mm) lifting heights with single stage mast

- Custom sizes and configurations available

- 115 VAC or 230 VAC automatic battery chargers

- Spare mandrel holder

- Anti-telescoping attachment with manually applied, padded O.D. clamp

- Expanding mandrels from 3” (76.2 MM) to 12” (304.8 mm)

- Automatic mandrel retractor for loading/unloading cantilevered mandrels

- Electric remote mandrel gripper retract

- Manual remote mandrel gripper retract

- with two 110 Ah batteries

- *Actual capacity depends on roll width and roll weight combined.

DR-EVO Drive Steering:

LED Batter Charge indicator, “turtle” switch for variable seed control and safety reversing switch.

Recharging:

A batter charger is built-in to the control housing and includes a 22-VAC power cord.

Traction & Stability

Structure with 5 contact points and shock-absorber system for perfect grip from the drive wheel. Ideally suited for floor irregularities.

Maintenance

High frequency 24V microprocessor controls with LOD function indicators allow fast and easy troubleshooting.

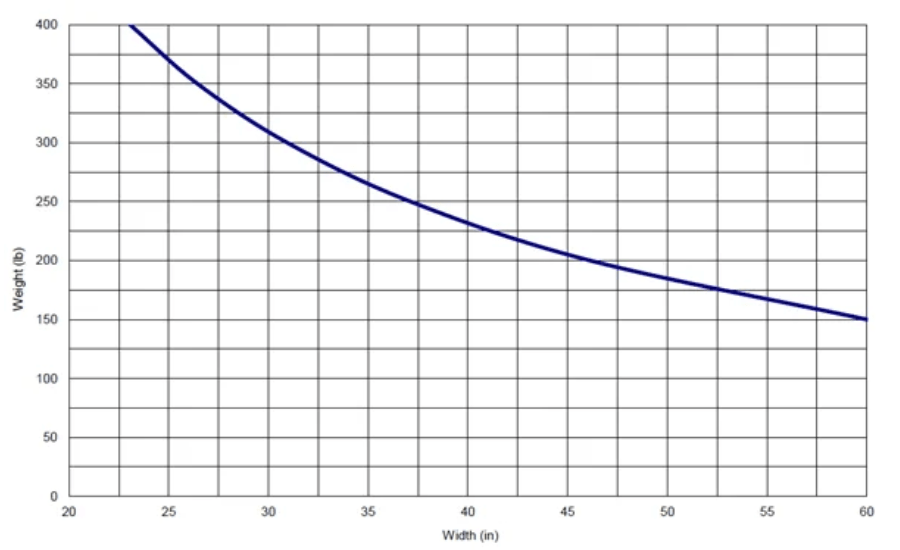

Capacity Chart to determine if your roll can be handled with the HD-1500

Super Heavy Duty

SHD 3000

The SHD-3000 super heavy duty roll handling machine with 3,000 lbs (1,361 kg) of lifting capacity, is precise in its movements and is our most powerful battery powered walk behind roll handling machine that we offer. The SHD-3000 is used to lift and turn rolls by the core for all types of roll handling applications like palletizing, transporting and loading roll into processing machines. This machine is designed to grip rolls from the inside the core without contacting the rolled material thus reducing the risk of both material damage and operator injury and therefore, saving your company money and valuable resources. With its powerful battery powered electric hydraulic lift & drive unit, driving and maneuver even in crowded work areas is safe and easy. Both the lifting and turning functions are powered by the unit’s hydraulic system. Lever control valves allow lifting and turning in minute increments allowing the operator to make precision alignments fast and easy.

SHD 3000

3,000 LBS Capacity

Click Below To Learn More About

The SHD Roll Handling Machine

SHD 3000

Lifting Capacity Up To 3,000-LBS

Standard Features

- Two speed drive with Turtle / Rabbit switch

- Precision oleodynamic control valves

- Powerful industrial batteries

- Ergonomic drive tiller

- Belly bump reversing switch

- Keyed lock switch and Emergency Stop

- Non-marking wheels

- Reliable electronic controls

- Rugged heavy-duty construction

- All cables and hoses housed within mast assembly.

Specifications

- Max Lifting Weight: 3,000 lbs (1361 kg)*

- Pallet Width Max: 48″

- Vertical Travel: Up to 63″ (1600 mm)

- Travel Speed: Variable

- Machine Weight: 895 lbs (406 kg)

- Painted steel construction

- 24-volt DC operation with two 110 Ah batteries

- *Actual capacity depends on roll width and roll weight combined.

Optional Accessories

- Fixed straddle, adjustable or Euro pallet legs

- 63” (1600 mm) lifting heights with single stage mast

- Custom sizes and configurations available

- 115 VAC or 230 VAC automatic battery chargers

- Spare mandrel holder

- Anti-telescoping attachment with manually applied, padded O.D. clamp

- Expanding mandrels from 3” (76.2 MM) to 12” (304.8 mm)

- Automatic mandrel retractor for loading/unloading cantilevered mandrels

- Electric remote mandrel gripper retract

- Manual remote mandrel gripper retract

DR-EVO Drive Steering:

LED Batter Charge indicator, “turtle” switch for variable seed control and safety reversing switch.

Recharging:

A batter charger is built-in to the control housing and includes a 22-VAC power cord.

Traction & Stability

Structure with 5 contact points and shock-absorber system for perfect grip from the drive wheel. Ideally suited for floor irregularities.

Maintenance

High frequency 24V microprocessor controls with LOD function indicators allow fast and easy troubleshooting.

Capacity Chart to determine if your roll can be handled with the SHD 3000

Manual Hydraulic Roll Handlers

Excels in all low to medium cycle roll handling operations.

Our most economical floor based Roll handlers are built tough for longevity yet nimble for ease of movement.

MRH-300 Portable Floor Based Manual Roll Handling

The MRH-300 is a manually powered portable roll handling machine designed as an uncomplicated device for lifting and turning applications. It is available with a variety of tooling options that allow the machine to be configured to perform many different tasks.

Tooling options available include Roller Probes, Straight Probes, “V” Cradle Platforms, Flat Platforms, Manual Roll Turners & Shaft Cradles.

Specifications:

Capacity – 300-lbs

Max roll diameter- “

Max roll width- “

Overall dimensions- 37″ L x 33″ W x 75 ” H

Outrigger ID-25″

Hydraulic travel-40″

Raised height-48″

Lowered height-8″

Additional height positions-up to 20″ more on 2.5″ centers

Machine weight- 316-lbs

Options:

Expanding mandrels from 3″ (76.2 mm) to 12″ (304.8 mm)

Various tooling options such as: Interchangeable probes, probes with rollers, shafted cradle, roll cradle, flat platform, V-platform and manual turner.

HRC Hydraulic Lifting Carts

The HRC series of hydraulic lifting carts are available in 300, 500, 1,100 and 1,700-lb capacities. Each unit has 2 fixed and 2 swivel casters for ease of transport and maneuvering. It is equipped with an ergonomic handle bar for operator convenience. Vertical lift powered by manual hydraulic foot pump. Lowering controlled by a manual relief valve.

Platform Options:

Roller bed platform.

Manual 360 deg swivel V-groove platform.

Front to back V-groove lifting platform.

Side to side V-groove lifting platform.Max roll width- 42″

Max roll diameter- 48″

Platform lowered height- 8.5″

Platform raised height- 29″

Cart dimensions- 34″ L x 18″ W x 37″ H

HRH 1000

The HRH 1000 is ideal for narrow web machinery with cantilevered unwinds and rewinds such as label presses, die cutters, inspection machines, laser printers and doctor machines. The HRH’s roller probe makes lifting, transporting, loading and unloading rolls with weight to 1,000 lbs (450 kg) fast, easy and completely safe. No more bending over to access rolls on low-mounted spindles. With its maneuverable, light weight and compact design, the HRH is ideal for crowded machine floors and press rooms.

*Custom configurations & tooling are available upon request.

Specifications:

Capacity-1,000-lbs

Max roll diameter- 40″

Max roll width- 16″

Overall dimensions-28″ L x 35″ W x 52″ H

Outrigger ID-27″

Probe length-17″

Hydraulic travel-10″

Roller probe lowered height-7.5″

Roller probe raised height-17″

Additional height positions- up to 20″ more on 2.5″ centers

Machine weight- lbs

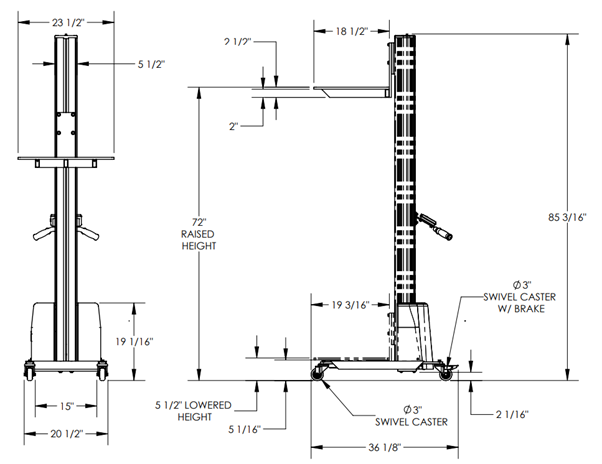

Light Duty Budget Friendly

These units are lightweight, DC powered and are quiet running when activated. Used to transport and position your rolls weighing up to 125-lbs with just the push of a button. Lift capacity will vary depending on the type of tooling you choose. The unit features a slim-profile design for maneuvering in narrow aisles and confined spaces. The polyurethane wheel casters consist of two swivel and two swivel-locking which allows the operator to position the load with increased precision. The DC battery powered system includes an AC on-board charger and includes a touch-pad controller allowing for easy up/down operation and battery power monitoring.

Specifications:

- ALUMINUM CONSTRUCTION

- LOWERED HEIGHT IS 5 1/2″

- RAISED HEIGHT IS up to 72″

- TOUCH PAD CONTROLLER

- 24V DC POWER

- MAX CAPACITY IS *125 LBS.

- Ø 3″ POLY ON POLY STEM CASTERS

- 2 SWIVEL W/ BRAKE & 2 SWIVEL

- HORIZONTAL LAOD CENTER- 9”

- LIFT SPEED- 15 SECONDS UNLOADED

Optional Tooling Attachments

Single Spindle

Single Spindle

Dual Spindle

Remote Controller

Hook Arm Attachment

Customizing Available

Dimensional Information

Automatic Roll Up-Ender Palletizing System

HRUP-5000

Designed to automate your roll stacking & palletizing operations and at the same time reduce manhandling injuries and product damage. The HRUP-5000 can be integrated with a host of other converting and conveying equipment providing an economical alternative to a completely automated handling system. With the use of the optional “multiple-V” back deck and the “pusher tool” the HRUP-5000 can stack multiple rolls and center them into position ready to be conveyed to the next station or can be moved away via forklift truck.

Specifications:

- High speed hydraulic turning

- Wireless keyed remote control with E-Stop

- Convenient floor mounting holes

- Rugged steel construction

- Powder coated finish

- Max load capacity: 5,000 lbs (2,260 kg)

- Max roll diameter 50″ (1270 mm)

- Pallet width max: 48″ (1220 mm)

- Pallet depth max: 54″ (1370 mm)

- Travel: 90º

- Travel speed: 0 to 90º in 18 seconds

- Machine weight: 2,000 lbs (906 kg)

- 230-460 VAC x 50-60 Hz x 3 phase power

Options & Accessories

- Flat top or roller bed on output side

- Flat or V cradle top on input side

- Pusher to center turned rolls on pallet

- Guide to prevent pallet movement when centering rolls

- Micro pendant with tethered remote

- Custom configurations available

- Light curtain guarding

Roll, Coil & Reel Movers

Safely Move Metal Sheet Coils, Large Reels & Heavy Paper Rolls On A Film of Compressed Air with Ease.

ASE System’s Roll, Coil & Reel systems (RCRS) literally float heavy stock on a thin film of compressed air. This patented technology makes it possible for one person to easily maneuver heavy loads without the use of a bulky forklift or floor track system. As little as one pound of push can move 1,000-lbs of weight, so one person can smoothly transport, rotate and precisely position even the largest and heaviest rolls, coils and reels. Our RCRS use standard shop air to instantly float and move heavy rolls in any direction.

They are equipped with a fixed full width handle, guide wheel, pressure regulator and on/off ball valve. An optional handle mounted throttle control is also available. With our line of Roll movers you get easy, dependable, omnidirectional control without hazardous fumes and noise.

"OD" Roll Lifting & Rotating Machine

Gripping Rolls Fromthe Outside Diameter

Reel Rotator with straddle outrigger legs– handling of heavy reels from all pallet types. When heavy rolls placed on closed pallets are to be transported, lifted and rotated, the Roll Rotator with straddle legs is the perfect choice! It can grip and place rolls, which are located on all types of pallets. It is compact, very maneuverable and ensures the user ergonomically correct working conditions. The gripping arms have rubber-covered gripping pads to achieve the highest friction possible and to ensure a gentle grip. The Roll Rotator can handle soft as well as hard reels up to an impressive 50” in diameter. High focus on safety! None of the models can open the gripping arms by mistake, which means the rolls can only be released, when placed on the floor or on a pallet. On models with electric rotation it is only possible to rotate at lifting heights above 29.5”, so the gripping arms will not collide with the floor or legs. The Roll Rotator with straddle legs is available in four unique models, with manual or electric rotation, roll gripping/releasing, manual or power lifting and manual push or power drive options.

Efficiency and Flexibility:

- Capacity 500 kg

- Handles vertical reels placed on floor or pallet and horizontal and vertical reels that are clear off the floor

- Handles reel diameters from Ø120 mm to Ø1270 mm (gripping arms can open 1300 mm)

- Manages soft as well as smooth and hard reels

- Also available without straddle legs

Safety:

- None of the models can open the gripping arms by mistake

- The reels can only be released, when placed on floor or pallet

- The reel is fixed with gripping arms

- The gripping arms have rubber-covered gripping pads to achieve the largest friction and to ensure a gentle grip

- On models with electric rotation, it is only possible to rotate at lifting heights above 750 mm, so that the gripping arms cannot touch floor or legs.

Facts:

- The tilt degree can be set for every 90° (with a locking system)

- Two lifting speeds: Normal and quick

- Two speeds for reel fastening

- Steering on both wheels

Durability:

- Strong construction

- Long operating life

- Low maintenance costs

Digital Controller:

- Large display – easy to use, easy visual presentation, touch screen

- Possible to program e.g. several stops, turning angle, speed, rotation

- Log function, e.g. operational time, current consumption, number of operations, overload registration, battery status

- Shows error messages and actual position/turning angle

- Supervisor function can be activated to lock the settings