Tool & Load Balancers

Air Balancers and Electric Balancers

Air Balancers and Electric Balancers are critical components in Vacuum Hoist Lifting Systems, offering precise control and smooth handling of heavy loads. Air balancers utilize compressed air to provide effortless lifting and lowering, ensuring a delicate balance between load weight and operator control.

Air Balancers

The Demag D-BP II Air Balancer is ideal for assembly processes in a variety of manufacturing environments including the most demanding automotive applications.

Its jerk-free, continuous three-dimensional movements provide the precision needed for fragile loads. The Load Weight Compensation feature assures

loads of different weights are lifted at almost identical, safe speeds and picking up and setting down can be accurately controlled. Load Balancing feature allows loads to be floated almost effortlessly where they need to be. The ability to use fast lifting speeds makes the D-BP II the optimal solution for fast pick-and-pack operations.

Technical Features

- Significantly higher lifting/lowering speeds possible (adjustable up to 6.5 ft./second)

- Very silent operation compared to chain hoists, far below 70 dB(A)

- Load balancing without the use of buttons for up to 150 lbs. is available as an option

- The load weight compensation safety feature is standard for all up/down control systems

- No jerky movements during lifting/lowering procedures, and no shock load

- No polygon-effect at all

- Duty cycle 100%, even with low speeds

- Market leading range of options to suit almost any application

Safety Features of the D-BP II Air Balancer

- Patented overspeed brake

- Load weight compensation for up/down air balancers maintains a safe speed independent of the load being lifted

- Interlock function can prevent an accidental release of the load from a suspended gripping device

- Baseload function keeps the air pressure at a safe level, enough to balance the weight of the gripper.

Economic Features of the D-BP II Air Balancer

- Higher speeds result in shorter cycle times and more efficient and cost-effective operation

- Wearing-free overload protection

- Simple maintenance – rope exchange in less than 15 minutes

- Almost unlimited lifetime, with little maintenance required

Demag D-BP II

See Our Air Balancers

In Action

Electric Balancers

Easy, Extremely Efficient Intuitive Load Handling Rated At The Top Of The List In Ergonomic Value.

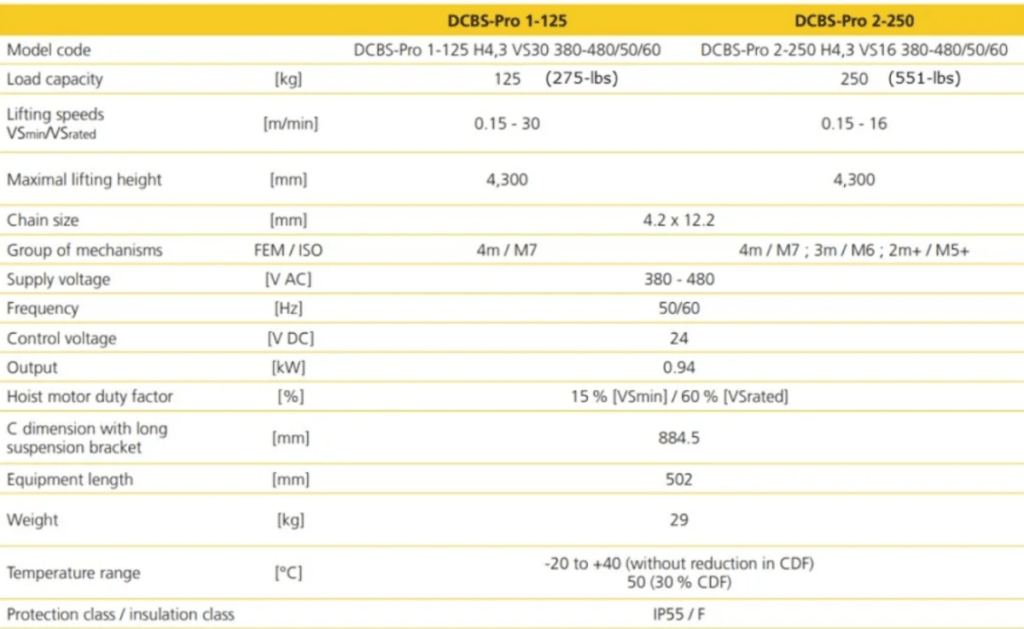

The DCBS Electric Balancer is part of our DC chain hoist line, allowing loads to be guided and precisely positioned with ease, making it a vital lift assist device for your operations. Our chain hoist balancer DCBS units are available in two sizes with load capacities of 275 & 550 pounds. Additionally, these electric balancers are compatible with all enclosed track, light rail and I-beam crane systems. DCBS units can easily travel on steel and aluminum profile section rails: on single-girder suspension cranes, suspension monorail systems, or on slewing jib cranes. This gives you a range of application options to use your electric balancer.

DCBS Electric Balancer

See How To Handle Loads

up To 350 LBS

Safety and Reliability

Core Functions Of Our DCBS Chain Hoist Electric Balancer:

- Lifting and lowering by manual force on the control handle

- Manipulating loads

- Protection against slack chain

- Protection against snatching loads

- Movements can be stopped if loads fluctuate widely

- Monitoring/reducing load capacity

Quality

Performace

Value

Protection

Ergonomic Lifting Devices

Designed With Safety In Mind.

Features that help your facility and its operators:

- Low-wear brake thanks to regenerative braking

- No need to adjust the brake

- Brake arranged before slipping clutch in the drive arrangement to eliminate load slipping

- Automatic braking if a malfunction occurs

- Slipping clutch with automatic cut-out by means of speed monitoring for no continuous slipping

- Gearbox, slipping clutch, and brake maintenance-free for up to 10 years

- Safety-related functions satisfy at least Performance Level C and Category 2 to EN ISO 13849-1

Additional Features:

- Operating limit switches (upper/lower)

- Elapsed operating time counter

- Installation transparency thanks to operating data interface (IDAPSY)

Technical Data