Acer Manipulators

The Acer series of manipulators are the newest members in our ergonomic lift assist family line up.

The lifting mechanism consists of a double rope assembly and pneumatic cylinder which allows for balanced movements, both with and without a load. Each Acer includes a standard safety hook for lifting or can be provided with specific gripping tools such as vacuum cups, powered grippers, magnetic grip, fashioned hook or fork, expanding mandrels or customized tools built to your exact specifications. The Acer is ideally suited for repetitive lifting tasks where overhead access to the pick-up and drop off points are free and clear of any obstructions either overhead or otherwise and, is best placed in small work cell areas & progressive assembly line applications.

The manipulator includes an “CE certified” accumulation tank to allow the operator to carry out the handling process in case the main air supply fails, dual wire ropes are provided for added safety and the boom includes a disc brake & caliper braking system to mobilize arm movement when needed; one is located at the main axle & column and one between the primary and secondary arms. The Acer is very easy to handle, lightweight, quick-moving and also employs our “Plug & Play” maintenance technology which allows your personnel without needing high technical expertise to replace critical pneumatic components that can be purchased from local supply house organizations thereby greatly reducing any downtime should the need arise.. Call on our skilled sales staff and expert engineers to experience our special blend of creativity, service & knowledge and we will provide you with an ergonomic handling solution on your next project.

Click below to see demonstration videos

of ACER Industrial Manipulators.

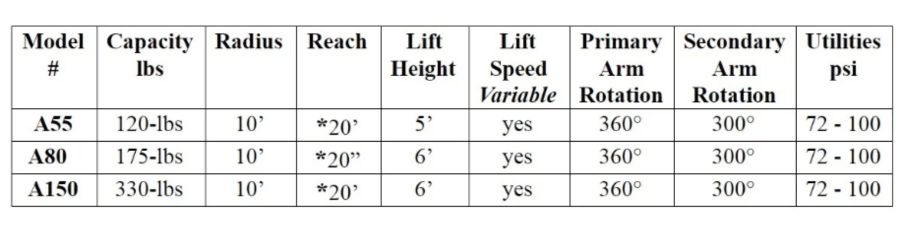

Acer 55

Acer 80

Acer 150

- Column mounted fixed to floor

- Column mounted attached to mobile base

- Overhead fixed position

- Overhead, under-hung attached to enclosed track rail systems

- Mount to your building column or wall mount position

- Increased productivity

- Superior control & manipulation

- Safe handling of heavy & awkward loads

- Lower labor costs

- Specialized training is not needed

- Gender friendly operation

- Decrease operator fatigue

- Safeguards delicate loads

- Improve quality assurance

- Multiple axes of manipulation

- Precise placement

- Float mode capability

- Pneumatic overload circuitry

- Reach in, under & around obstacles

- Easy function controls

- Powered & manual gripping

- Vacuum cup

- Magnetic

- Expanding mandrel

- Multiple combinations

- Customization for your requirement

- Automotive assembly (engines, transmissions, chassis & interior components)

- Aerospace (progressive assembly lines)

- Heavy equipment manufacturing

- Defense contractors

- Tool & die swap outs

- Modular home, shelter & building manufactures

- Natural gas & oil industry (valves, drilling components, etc)

- Clean rooms

- Repetitive lifting jobs

- Parts assembly

- Food manufacturing & related supply industry

- Machining

- Process equipment maintenance

- Many more…