Air Powered Drive Units

Steerable – Air-Motor Powered Drive Units for Moving, Controlling, and Positioning Heavier Loads.

(optional pendant controller available)

The Air Drive moves the equipment at varying speeds up to a maximum of 40 feet / minute requiring only compressed air as a power source. Thumb controls with motorcycle style grips give the operator precise variable speed control in both the forward and reverse directions. The drive is equipped with a quick attach feature to allow simple connection and removal from the load. This allows a single drive to be shared by many pieces of equipment with the purchase of additional quick attach plates. The quick attach feature also allows the drive to be stored out of the way when not in use. The operator’s control console has an on/off switch, emergency stop, and gauges to monitor air inlet pressure and drive wheel traction pressure. The drive has two (2) air stroke actuators that force an elastomeric drive wheel down against the operating surface. The drive wheel traction pressure control located on the operators control console controls the amount of drive wheel “down” force, hence the amount of traction. The pressure in the air stroke actuator is monitored by the pressure gauge located on control console. The pressure also functions as an automatic air suspension system for a smooth ride. Drive torque is transmitted to the drive wheel by a piston style air motor through sprockets and chain and develops over 1200lbs of draw bar more than enough to move and control the load. This motor has been designed for high torque at low speeds with finite control for load positioning. The piston style air motor provides the additional advantage of providing dynamic braking which helps slow the load travel speed when the throttle is released. The drive housing is constructed heavy wall plate for superior durability in a harsh industrial environment. The drive also includes an integral filter lubricator to simplify the interface process and maintenance program.

Each drive consists of a drive housing with a high-torque air motor, pivoting steel handle, control panel, and a single QA Plate.

- Attachment: The Air-Drive attaches to the load with a dual-post Quick-Attach (QA) system that is specially designed t provide a rigid connection that can be uncoupled for flexibility. The QA system incorporates a dual-post QA plate that is bolted or welded to the load structure and a mating connection designed into the Air-Drive. This allows the drive to be removed or connected to multiple loads or attachment locations. A drive would normally be designed for attachment to a structure that includes a Guide Wheel for car-like steering. Two drives may be connected to a structure on each end for greater omni-directional steering options or move precise positioning.

- Options: Available options include Guide Wheel & Controls, Remote control pendant, internal drives, and extra QA plates.

Want More Details?

Check Out Our Diagrams And

Information Guide.

Check Out Our

Power Drive Demo

Battery Powered Drive Units

LD-1501 SYSTEM STANDARD FEATURES:

- Battery operation for ease of use

- Quick attachment mechanism

- Built in battery charger for charging

- Traction control for ease of use

- Automatic reverse if drive becomes stuck against an object

- Foam filled tires to eliminate flats that typically plague pneumatic style tires

- Detailed operation manual

SYSTEM SPECIFICATIONS:

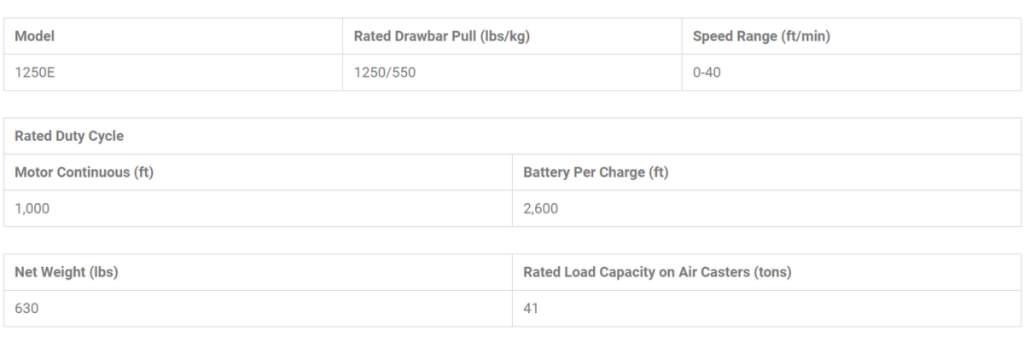

- Drawbar: 1,250 pounds

- Speed: 0 – 40 feet per minute

- Duty cycle: Motor 1,000 feet continuous

- Battery life per charge: 2,600 feet

- Weight: 1,900 lbs.

OPTIONAL FEATURES:

- Handle mounted safety switch requires two-hand operation

- Strobe light – motion activated

- Horn – motion activated or button operated

- Speed Range – 0 up to 80 feet per minute, variable