Self Powered Mechanical

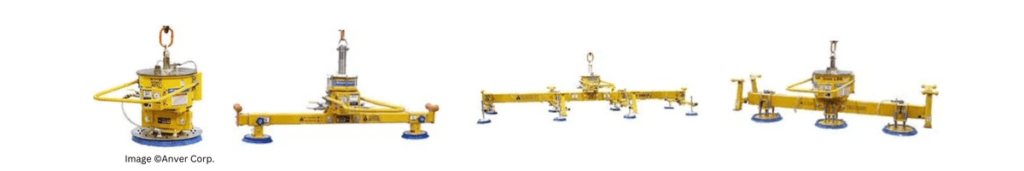

Self Powered Mechanical Lifters can be equipped with a variety of Interchangeable Vacuum Pads and Vacuum attachments for a wide range of material handling applications. Various single and multiple pad configurations can be installed on most of our standard vacuum generators.

Self Powered Mechanical Lifters

Mechanical Lifters

Click below to see a demonstration video.

Lift Features:

- Instant attach and release is provided via the hoist up and down movement. The attach and release alternates each lift cycle for fast, efficient handling. Mechanical vacuum lifters increase the speed and efficiency of the horizontal handling of sheet and plate, panels, and all types of nonporous materials.

- Simple to operate. One person can control the entire operation. No oil fumes or noise pollution.

- Easy to Maintain. Only the highest quality components and superior construction are used with few moving parts.

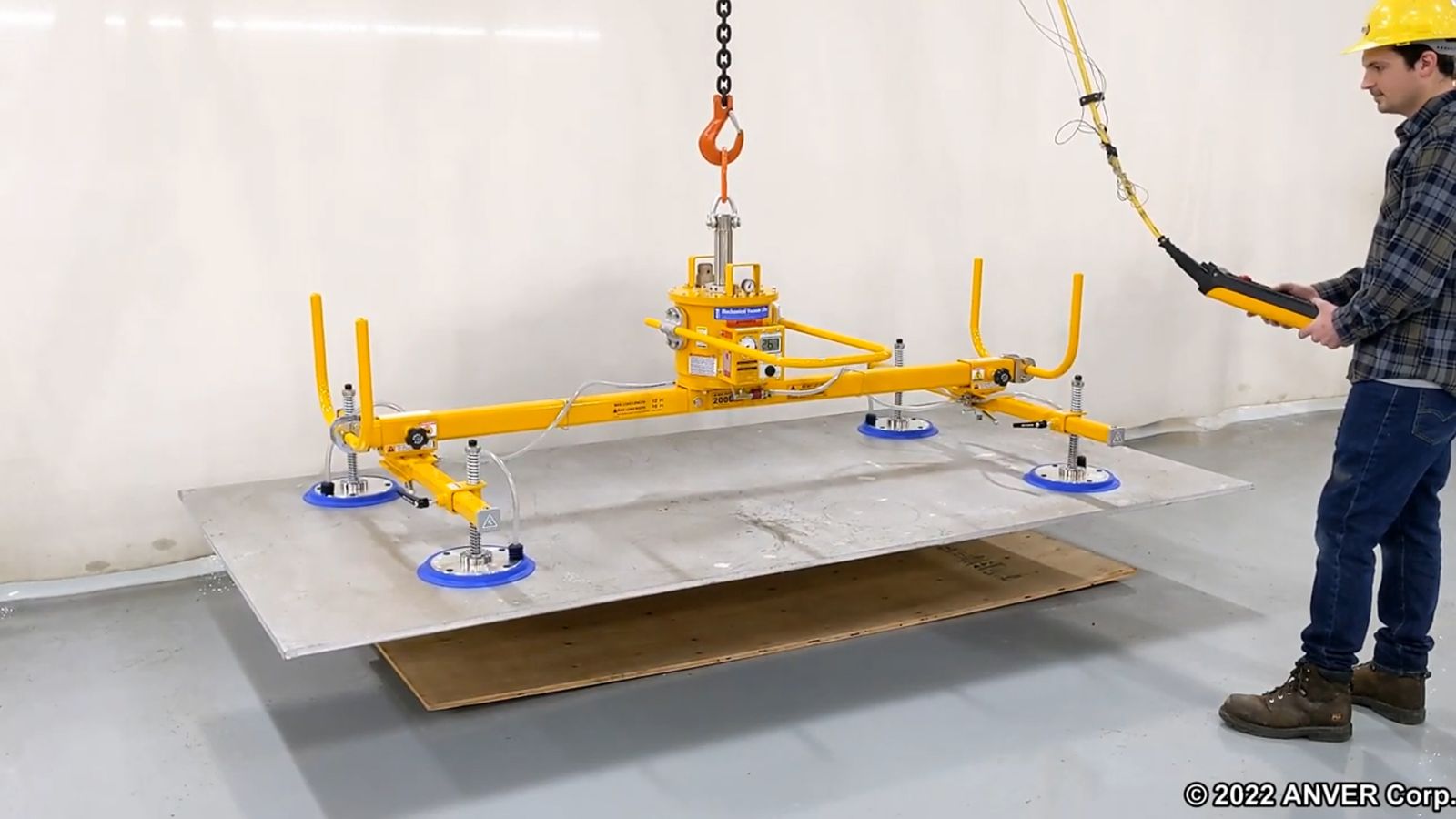

- Pivoting cross arms and vacuum cups are fully adjustable to fit a variety of sheet sizes.

- Non-marking vacuum suction cups with bottom springs for even attachment. Top springs provide even loading when lifting. Ball-in-socket articulated suspensions permit handling wavy or blocked plate.

- Extremely Safe. Load cannot be released until it is set down on a surface.

- Mechanical Vacuum Lifters are suitable for 100% duty cycle 24 hour a day operation. They never overheat or burn out.

- Each vacuum suction cup supports an equal amount of the load weight with less than 2 inches (51 mm) of sag or droop.

- Easy to Maintain and Keep Operating in Heavy Production Environments. SSR Snap-In Sealing Rings are used to allow for cup replacement in seconds without tools. No wires or hose to tangle up in the hoist chain; no fuses, motors or switches to replace. Mechanical Vacuum Lifters cannot overheat and are not affected by electric power brownouts.

- All of ASE Vacuum Lifter comply fully with and meet the standards of US ANSI ASME Standard B30.20 for below-the-hook lifting devices, as well as complying with OSHA and European requirements.

Mechanical Vacuum Lifters do not rely on plant power, outside controls, or complex accessories. These self-contained units create their own vacuum mechanically, giving them unmatched versatility for use in metal fabricating plants, service centers, warehouses and plate yards. These lifters offer instant attach and release via the hoist up and down action. The internal piston and non-wearing rolling diaphragm create vacuum and will work silently with minimum maintenance for years.

One person can easily attach the hook of the overhead crane, hoist, or boom crane to the lifter, position the lifter on the load and control the entire operation alone. The attach and release alternates each lift cycle for fast, efficient handling. Mechanical lifters increase speed and efficiency of horizontal handling of sheet and plate, fabrications, panels, and all types of non-porous materials.

Eight Pad Self-Powered Mechanical Vacuum Lifter

For Lifting Trailer Body Panels 16 ft x 8 ft (4.8 m x 2.4 m) weighing up to 1200-lbs (544 kg)

- Unequaled productivity: self-contained mechanically actuated unit ideally suited for handling metal sheet and plate.

- Easy installation: merely suspend the vacuum lifter from your overhead hoist hook and its ready for service.

- Self-cycling control: as the lifter is raised and lowered via the overhead hoist, the built in cycling cam operates the attach and release mechanism.

- No buttons to push or knobs to turn and no electric wires or hoses to become tangled.

How Self Powered Mechanical Lifters Works:

UP/Down Movement of Hoist Controls the Vacuum Attach & Release. Simple On/Off Cycle is Quick and Reliable

Basic Operating Procedure

A. The mechanical lifter is hanging form the crane hook and is lowered onto the load until the chain becomes slack.

B. The lifter is pulled up by the hoist and picks up the load.

C. The lifter and the load are set down until the chain is completely slack.

D. The lifter can now be raised without the load.

E. Set the lifter down again until the chain is completely slack and it is then ready to pick up the next load.

Technical Data:

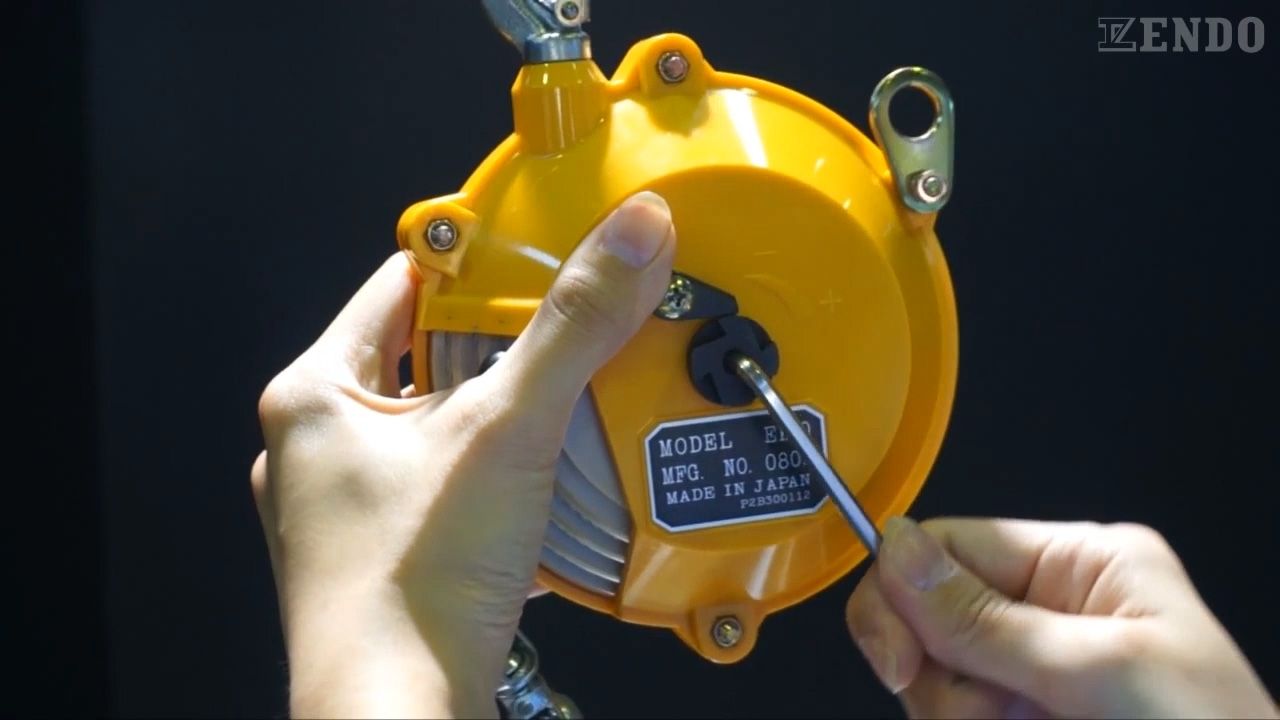

The vacuum generator of the mechanical lifter consists of a free-moving piston within a closed cylinder. A rubber rolling diaphragm forms an air tight seal between piston and cylinder. Since the integrity of this seal does not depend on metal to metal contact or a tight fit, it does not lose efficiency with use.

The vacuum attach and release cycle is controlled by an automatic self-cycling valve located in the bottom of the piston. When the unit is lowered onto the load and the suspension chain slackens, a cam automatically closes the piston valve. The hoisting action then pulls up the piston, creating a powerful vacuum inside the cylinder an underneath the vacuum cups. When the load is completely set down, and the suspension chain is again completely slackened, the cam opens the piston valve, releasing the vacuum; the lifter then can be raised and readied for the next pickup.

The attach and release functions are instantaneous. Since the valve sealing disc can only cycle when the chain is completely slack, it cannot shift positions while in use and accidentally release the load.

Get A Free Quote!

Air Casters & Bearings, Air Jacks & Material Handling Systems

OVERHEAD CRANES

As an innovator and leader in the industry, ASE provides a wide variety of overhead workstation crane solutions. Our work station systems include free standing work station bridge cranes, ceiling mounted bridge cranes, monorails, and work station jib cranes.

VACUUM LIFTERS

ASE Systems offers standard and custom material handling solutions for industrial and commercial environments, featuring self-powered vacuum lifters—mechanical, electric, and air-powered—with varied lifting capacities to meet your specific needs.

INDUSTRIAL MANIPULATORS

ASE Systems takes pride in offering a diverse selection of hi-end, cost-effective industrial manipulators. Meticulously designed, these manipulators ensure years of handling for all your challenging heavy, lifting applications successfully

LIFT ASSIST DEVICES

ASE Systems brings over 30 years experience specifying and designing ergonomic & productivity enhancing solutions to a broad range of industries that include: Aerospace, Defense Contractors, Manufacturing, Power Generation, Assembly, Marine and more.

ROLL HANDLING

ASE Systems offers a complete line of Roll handling and moving equipment including portable, stationary, floor and hoist based systems that can lift, move, turn, tilt and “up-end” practically any type of roll, coil and reel. These systems are available with fully powered functions.

AIR CASTERS

ASE Systems understands the importance of reliable equipment and offers a diverse range of solutions to meet these demanding needs. The safe, efficient, and effective movement of heavy loads & machinery is a critical aspect of any operation’s success.

TOOL / LOAD BALANCERS

ASE Systems brings over 30 years experience specifying and designing ergonomic & productivity enhancing solutions to a broad range of industries that include: Aerospace, Defense Contractors, Manufacturing, Power Generation, and more.