Lift & Tilt Tables

Tilt Tables

Designed for Simple, Safe, One-Person Operation

THE MODERN WAY TO HANDLE MATERIALS

- Allows one person to handle large, awkward loads. As the weight and maneuvering is done by the machine, back and hand injuries are eliminated.

- Increases the safety and efficiency of panel handling. The tilting of the load is controlled and accurate.

- Speeds feeding and unloading operations. The attachment and release is made within seconds.

- Eliminates product handling damage. Only soft, non-marking rubber cups touch the load surface.

- Ends the need to block loads for slings or clamps. The density of storage is increased while retrieval time is dramatically improved.

- Labor cost and product damage savings combine for an average return on investment of only 3 to 9 months. The cost justification is straightforward and the Lifter’s effectiveness will be immediately appreciated.

- Not only lifts, but rotates and upends to

Lift & Tilt Tables

THE MODERN WAY TO HANDLE MATERIALS

- 250 to 4,000 lb. capacities, up to 46 in. lift

- Table tilts up to 45 degrees for load handling ease Lifts load from ground level to desired height and then tilts the load for easy handling.

- Increases worker productivity and morale

The Lift and tilt tables put work within easy reach of the worker for increased productivity, safety and morale. - Reduces fatigue and increases worker safety

Virtually eliminates bending, reaching, stretching and lifting, reducing worker fatigue and the risk of back injuries. - Remote controls available

Elector-hydraulic operation is commonly used with either push-button or foot-pedal remote control.

Compatible Equipment:

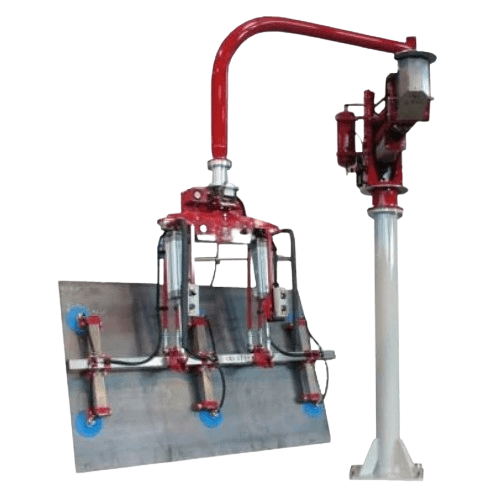

Vacuum Tube Lifting Systems

Ergonomic Vacuum Lift Assist’s advanced design breaks the barriers of traditional high vacuum systems.

- Handles a greater variety of material

- Reduces the risk of damaging your material

- 40% more efficient than traditional high vacuum lift systems

- Eliminates the need for a smooth, non-porous surface

- Transport your most delicate materials safely

- Handles the same load with less horsepower and more savings

Manipulators

Manipulators have virtually unlimited applications with ends specifically designed to your needs.

Use for off center loads, reaching in or under and to keep work pieces square and stable.

- Manipulator Arms

- End of Hook Handling Devices

- Roll Handlers

- Custom Engineered End Effectors

- Anti-torque Arms

- Tool Balancing Arms

- Floor and Overhead Mounts

- Portable Bases