Gorbel Manipulators

Intelligent Assist Devices

Gorbel Manipulators are specialized lifting devices designed to assist with ergonomic material handling in various industrial settings. As part of Gorbel’s ergonomic lifting solutions, these manipulators are engineered to reduce the physical strain on workers, improve workplace safety, and enhance overall productivity. These highly ergonomic lifting devices are part of a family of material handling equipment known as Intelligent Assist Devices (IAD’s). They use exclusive patented technology and an industrial processor controlled servo drive system to deliver unmatched lifting precision and speed. Their fusion of advanced technology and basic human guidance maximizes productivity while minimizing the risk of injury to the operator.

- The perfect blend of high speed, productivity-boosting performance and ultimate precision placement in one lifting device.

- Float mode enables the user with ultra-fine, hands on part control for precision placement of any load while significantly reducing the potential for costly damage to the part being lifted or surrounding equipment.

- Input/output functionality with standard features that allow the intelligence of the G-Force® or Easy Arm® to elevate the intelligence of the total solution such as the anti-drop functionality for tooling control.

- Virtual Limits provide a powerful error-proofing tool for any application and eliminate the possibility of product damage from impact.

Gorbel Manipulators: Superior Efficiency in Lifting and Handling

Click Below to Learn More

About IAD's

Easy Arm Manipulators

Intelligent lifting device designed for high speed, precision pick & place activities, float mode capable & includes a host of programable selections.

G-Force Manipulators

A hoist based intelligent lifting device that can turn your existing overhead crane into the most advanced ergonomic lifting device.

Easy Arm Floor and Overhead Rail Manipulators

- FREE STANDING:

- Capacities: 165, 330

- Spans from 6′ to 14′

- Height under hook of 6′-11′

- Speeds up to 180 ft. per minute

- Cost effective turnkey solution

- UNDERHUNG:

- Capacity: 165 lbs.

- Spans to 10′

- Speeds up to 180 ft. per minute

- Mount to a ceiling or manipulator platform

- Cost effective turnkey solution

- No special foundation required

- Two pivot points make it easy to reach around obstacle or into machines

- Unmatched precision

- G360™ air & electric collector swivel assembly prevents tangled cables

- Ease of installation for reduced installation time & costs

- Slide, pendant, or force sensing handle options

- Teachable virtual limits

- Speed reduction points

- Shock absorbing end stop

- Latch hook

- Extended wire rope drop

- Slide on Air Hose

- Transformer

- Universal trolley adapter

- Automotive (engine assembly, transmission assembly, chassis components)

- Aerospace

- Heavy equipment manufacturing

- Tool & Die change-outs

- Natural Gas & Oil Industry (valves, drilling components, etc)

- Repetitive lifting jobs

- Parts Assembly

- Machining

- Palletizing loads

- Warehouse loading docks

- Process Equipment Maintenance

- Semi-Conductor

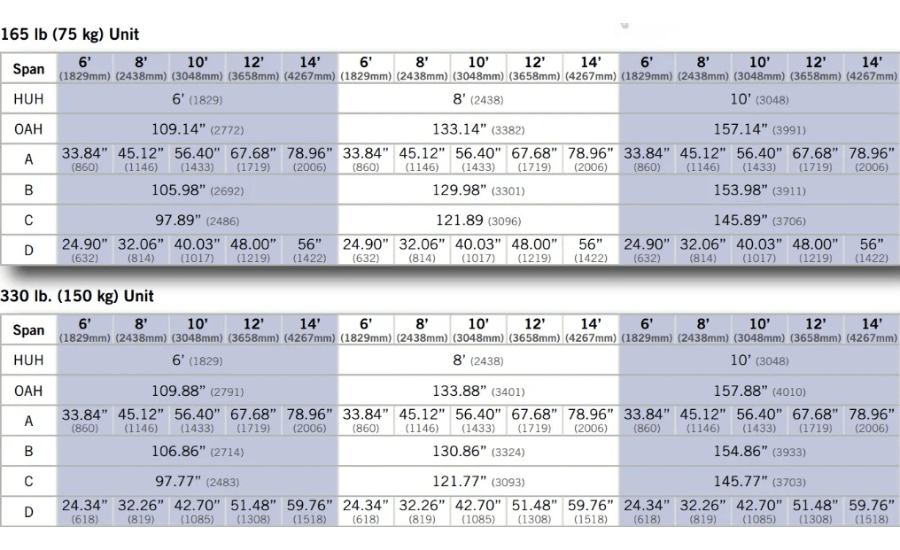

Technical Specifications:

Click below to see a demonstration video of our Easy Arm Manipulators.

Application Photos:

G-Force Hoist Based Manipulators

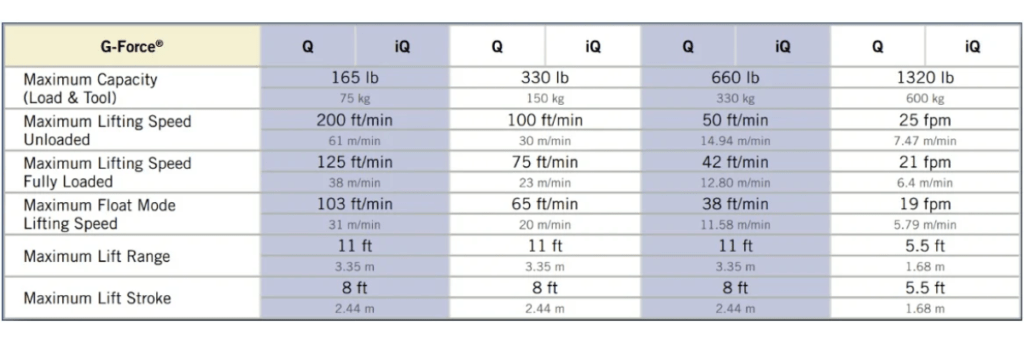

- Capacities from 165 to 1320 lbs.

- Speeds up to 200 ft. per minute

- Can cover multiple work cells

- Rapid return on investment through increased productivity and reduced product damage

- Decreases risk of operator injury creating a safer work environment

- Higher environmental ratings (more tolerant to dust and liquid)

- Enhances job performance

- Patented G360™ collector and swivel assembly prevents damage to coil and/or optional air coil

- Handle configurations are easily changeable in the field

- Intuitive servo-controlled lift

- Standard float mode capability

- Standard coil cords with in-field add-on air hose

- LCD on hand controller communicates more information like system status and diagnostics

- Seamless operator present function by means of a photo sensor

- Ease of installation for reduced installation time & costs

- Slide, pendant, or force sensing handle options

- Teachable virtual limits

- Speed reduction points

- Shock absorbing end stop

- Latch hook

- Extended wire rope drop

- Slide on Air Hose

- Transformer

- Universal trolley adapter

- Automotive (engine assembly, transmission assembly, chassis components)

- Aerospace

- Heavy equipment manufacturing

- Tool & Die change-outs

- Natural Gas & Oil Industry (valves, drilling components, etc)

- Repetitive lifting jobs

- Parts Assembly

- Machining

- Palletizing loads

- Warehouse loading docks

- Process Equipment Maintenance

- Semi-Conductor

Technical Specifications:

Click below to see a demonstration video of our

G-Force Manipulators.

Application Photos: