Roll, Coil & Reel Movers

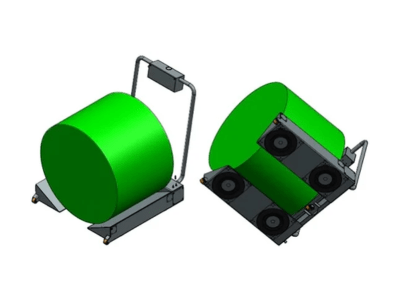

Safely Move Metal Sheet Coils, Large Reels & Heavy Paper Rolls On A Film of Compressed Air with Ease.

Roll Coil Reel Movers are specialized material handling equipment designed for the efficient transport and manipulation of large rolls or coils of materials, such as paper, fabric, wire, or metal. These movers are crucial in industries where materials are stored or processed in large roll formats, allowing for easy movement without damage. ASE System’s Roll, Coil & Reel systems (RCRS) literally float heavy stock on a thin film of compressed air. This patented technology makes it possible for one person to easily maneuver heavy loads without the use of a bulky forklift or floor track system. As little as one pound of push can move 1,000-lbs of weight, so one person can smoothly transport, rotate and precisely position even the largest and heaviest rolls, coils and reels. Our RCRS use standard shop air to instantly float and move heavy rolls in any direction.

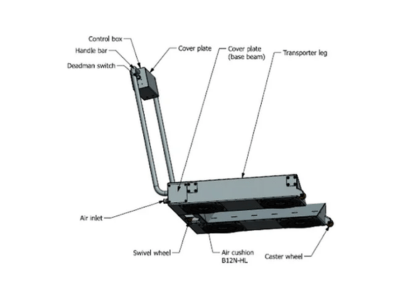

They are equipped with a fixed full width handle, guide wheel, pressure regulator and on/off ball valve. An optional handle mounted throttle control is also available. With our line of Roll movers you get easy, dependable, omnidirectional control without hazardous fumes and noise.

Transport:

Heavy Paper Rolls,

Metal Sheet Coils & Large Reels

ASE System’s air caster roll movers which allow the operator to move heavy inventory with the greatest of ease. ASE offers a complete line of paper, roll, reel and coil handling equipment that will help save time, increase productivity, and reduce the chances of worker injuries and damage to your product.

Save Time

Increase Productivity

Reduce Injury

Avoid Product Damage

Transporting heavy paper rolls, metal sheet coils and large reels can be a difficult, time-consuming task unless you use ASE System’s air caster roll movers which will allow the operator to move heavy inventory with the greatest of ease. ASE offers a complete line of paper, roll, reel and coil handling equipment that will help save time, increase productivity, and reduce the chances of worker injuries and damage to your product.

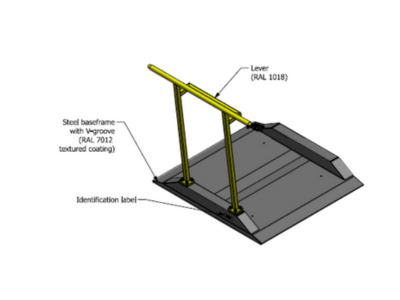

- Standard equipment includes inverted U-type handle, no-load wheels, pressure regulator and on/off ball valve.

- Standard configuration for no-load wheels is front 2 fixed, rear 1 swivel.

- Optional squeeze throttle control.

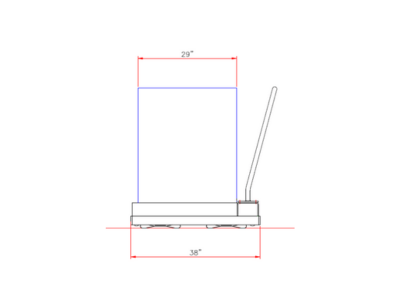

- Non-standard roll diameter ranges are available. Specify roll diameters between 24″ minimum and 84″ maximum.

Roll diameter specifications are based on hard paper rolls. If unit is to be used for soft paper, contact ASE to determine the correct equipment specification.

Want More Details?

Check Out Our Diagrams And

Information Guide.

Move Metal Sheet Coils,

Large Reels & Heavy Paper Rolls On A Film of Compressed Air

Equipment Description