Air Plank Systems

Designed for use with loads having minor variations in width, but large variations in length.

Set-up is easy and fast, requiring only one air hose connection. Air planks, a type of air caster, can be used in combinations of two or more to move long, complex machines such as printing presses or mail sorting machinery. Air plank systems utilize the efficiency of fluid film technology to actually float heavy loads on a near friction-less film of air.

Minimize Work Interruptions with Air Plank Systems

Air plank systems combine simplicity of operation with extreme versatility. Air casters are more cost effective than traditional load movement methods. With our Air plank systems, one person can easily move thousands of pounds.

Load movement is easy, exceptionally smooth, omni-directional and can be performed anywhere in the work environment where there is an adequate floor surface. I.E.: (Sealed, hand or machined trawled concrete or equal). Air planks distribute the load weight over a greater surface than with rollers or wheels, spreading any stress evenly on the floor. This eliminates damage to the floor and the need for expensive tracks, reinforced floors and building structures.

Using Air planks avoids time consuming and costly work interruptions, and machine dis-assembly and reassembly. Air planks are available in varying lengths and widths to accommodate almost any load configuration. Air Planks are frequently used in flexible manufacturing systems and assembly lines to replace cumbersome track, rail or in-floor conveyor systems.

Air planks offer unprecedented flexibility with omnidirectional movement and can free-up cranes and forklifts for other tasks. Uneven loads can be automatically adjusted using a single air pressure regulator in combination with built-in active flow controls.

Your personnel can quickly learn to utilize the system. With no moving parts, maintenance costs stay low. Air planks are specifically designed for applications where the load is long and narrow. They also excel in intermittent flow assembly lines and other station to station applications, and in situations where access is limited to only one side of a load. Air Planks can make it easy to transport and position heavy equipment such as heavy machinery, machine tools, medical equipment, mainframe computers and other sensitive electronic equipment. Air plank systems are ideally suited for progressive assembly operations.

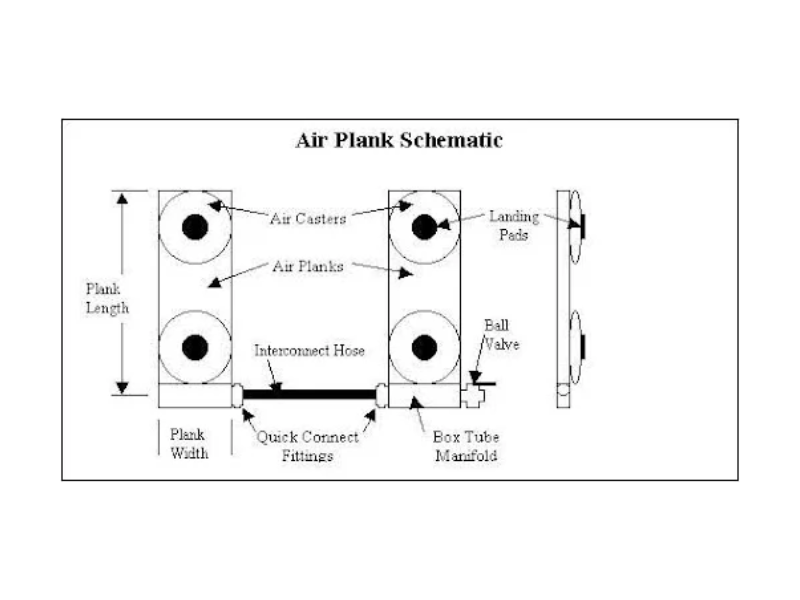

System Standard Components

Each system consists of two planks each having 2 or 3 air casters mounted to a high-strength extrusion. Each plank includes an air supply manifold on one end mounted flush with the top surface. Inside the manifold are flow control valves that automatically compensate for offset loads up to a 70/30 offset. Also included is one 10′ interconnect hose with quick connect fittings, one pressure regulator with gauge, and one on/off ball valve.

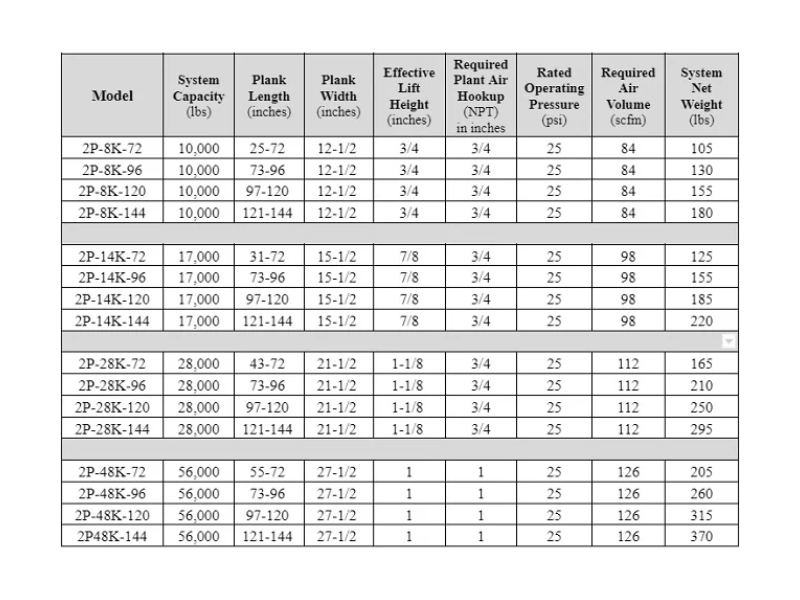

- Load must be positioned so individual bearing capacities are not exceeded.

- Recommended supply pressure: 25 psi above rated operating pressure at maximum load.

- Required floor surface: smooth trawled and sealed concrete or equivalent.

- Recommended for air supply hose lengths up to fifty (50) feet, consult sales engineer for longer lengths.