Air Pallet Systems

Move small heavy loads with precise omni-directional movements.

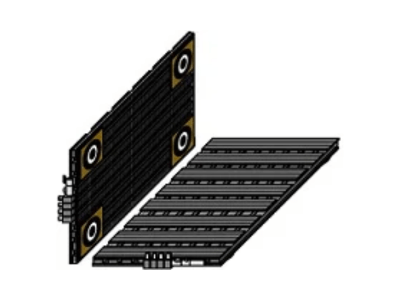

Air Pallet Systems are designed to allow one person to move heavy loads safely and efficiently. The aluminum extrusion pallets utilize the efficiency of the proven fluid film technology to float the load over the surface on a thin layer of air.

A Better Way To Move Heavy Loads.

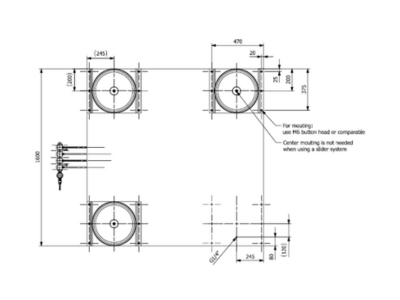

The aluminum extrusion pallets utilize the efficiency of our proven Air Casters and air film technology to float the load over the surface on a micro-thin layer of air. One pound of force will move 1,000-lbs of load. Utilizing the Air Caster Principal, an air film is created when compressed air is pumped into the circular Air Caster diaphragm and center plenum chamber.

When the air pressure in the Air Caster exceeds the weight of the load, air slowly and evenly escapes between the flexible torus bag and the floor surface to create a thin, friction-less film of air .003 – .005 inches thick.

Air Pallets with four or more Air Casters, are designed to operate under loads with similar dimensions. Air Pallets are ideally suited for small concentrated loads weighing up to 28,000-lbs. Easy to move loads in areas restricted by low ceiling and door heights.

Easy Maneuverability And Precise Movement.

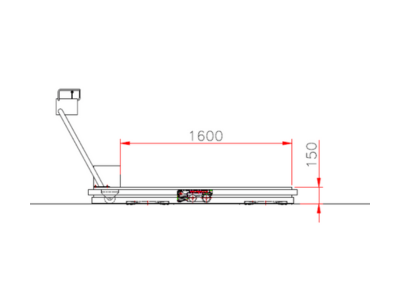

The film of air on which the Air Casters float provides omnidirectional movement capability that allows for exceptional maneuverability around sharp corners and within tight spaces. The low profile of the Air Pallet aluminum deck makes it easy to move loads in areas restricted by low ceiling and door heights.

Ideally suited for small concentrated loads weighing up to 28,000-lbs.

Easy to move loads in areas restricted by low ceiling and door heights.

Perfect for moving heavy bulky loads such as paper rolls and steel drums.

No costly maintenance! Move loads less expensively compared to other load moving alternatives.

Many Manufacturing Applications.

Lightweight aluminum extrusion air pallets are perfect for moving heavy bulky loads such as paper rolls, steel drums or other concentrated loads in warehousing and manufacturing applications. Automatic flow control valves compensate for offset loads and irregularities in the operating surface.

An air pallet is ideal for transporting loads in clean room environments, moving finished products to shipping and storage areas, precisely aligning machines over footings, moving modules, and rearranging entire production lines.

Safety Is Built In.

The system can be used around volatile liquids and gases safely, and your shop personnel are working in a clean environment without the side effects of internal combustion engine emissions. Low initial investment, operating & maintenance costs. Air Pallets can replace forklifts, cranes, pallet jacks and conveyors at a fraction of the cost. Pound for pound you can move loads less expensively compared to other load moving alternatives.

Air Pallet Systems work with standard shop air and there are no moving parts that require costly maintenance. Since Air Pallets float the load over the surface and the load weight is spread evenly, critical stress to the floor surface is virtually eliminated. Expensive tracks, reinforced floor and structures are not usually necessary.

Standard Equipment:

- Air manifold on one end of pallet with ¾” NPT fittings.

- Automatic flow control valves: automatically compensate for offset loads and irregularities in floor surface.

- Pressure regulator

- On/off valve for operator control

Options: Inverted U-shaped steel handle made of 1-1/2″ tubing. Ball valve and pressure regulator mounted on U-shaped handle.

Additional Options:

- Slide mounted Air Caster elements.

- Spring loaded No-Load wheels.

- No-Load swivel wheels.

- Supplementary lift bags (to provide extra lift)

- Roll Chocks-fixed (for reels and rolls).

- Automatic Roll Chocks

- Guide Wheels (to help the pallet track straight on long moves)